1. Natural Gas Annealing Furnace For Wire

Horizontal Hot Air Circulating Annealing Furnace with gas heating

Suitable for annealing and heat treatment of aluminum wire and aluminum alloy wire.

The natural gas annealing furnace generally adopts a large trolley type annealing furnace. The furnace type has large loading capacity and superior furnace temperature uniformity. Generally, it is used for large and medium-sized metal structural parts, gas storage tanks, containers, ships and welded parts below the rated temperature. For heat treatment.

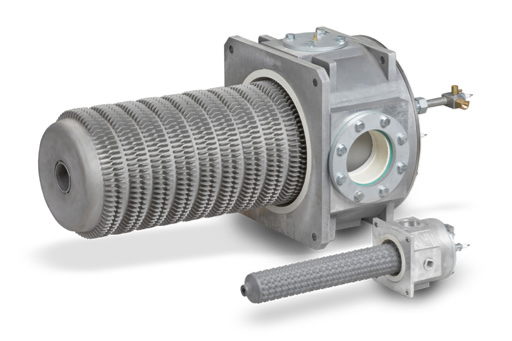

2. GAS BURNER

Self-recuperative burner A-Max for gas

- For direct and indirect heating

- Economical, energy-saving operation by virtue of internal air preheating up to 650°C

- Uniform distribution of temperature by means of a high burner impulse

- 7 sizes from 25 to 500 kW

- Highly efficient with a ceramic burled tube recuperator or a cast steel ribbed tube recuperator.

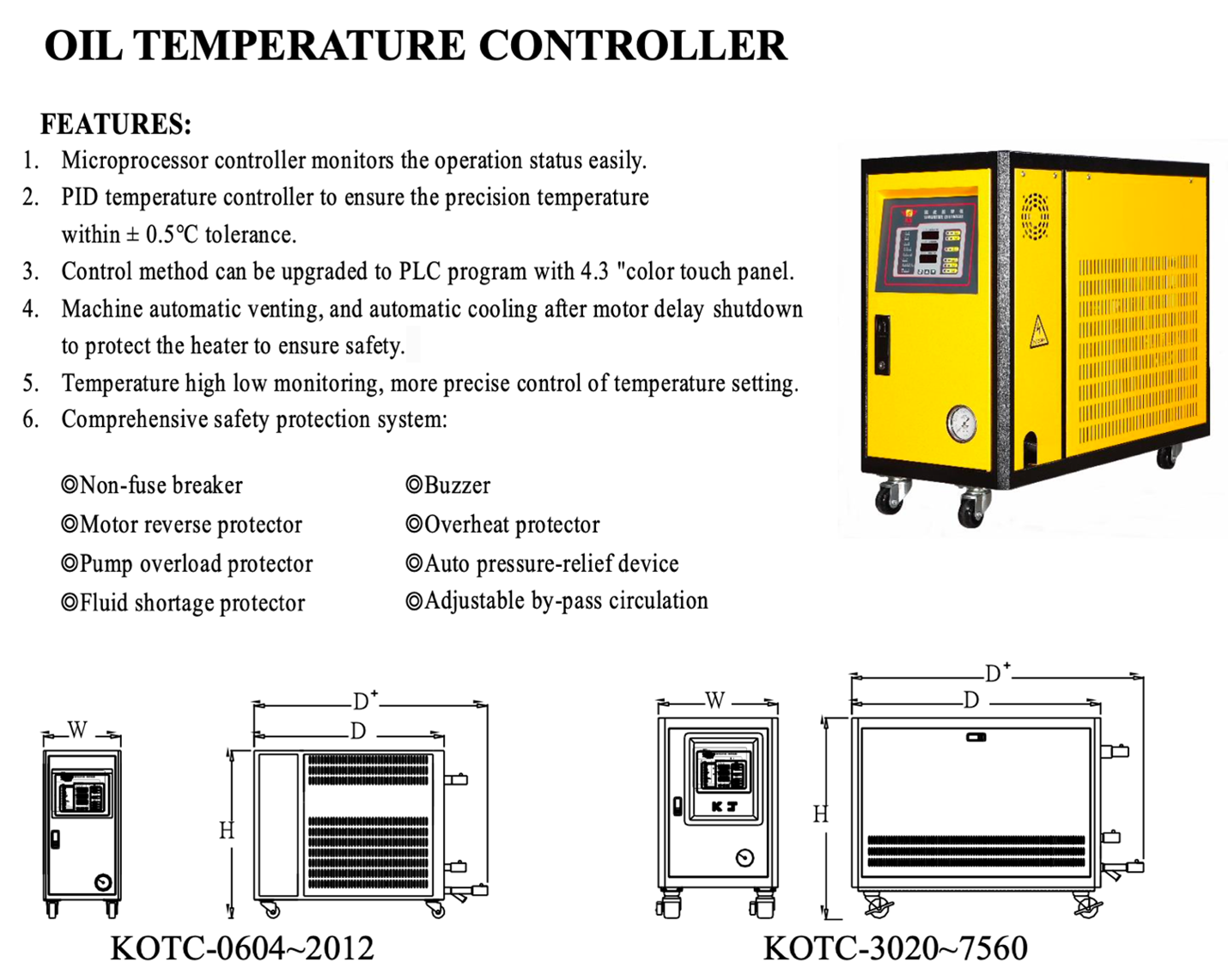

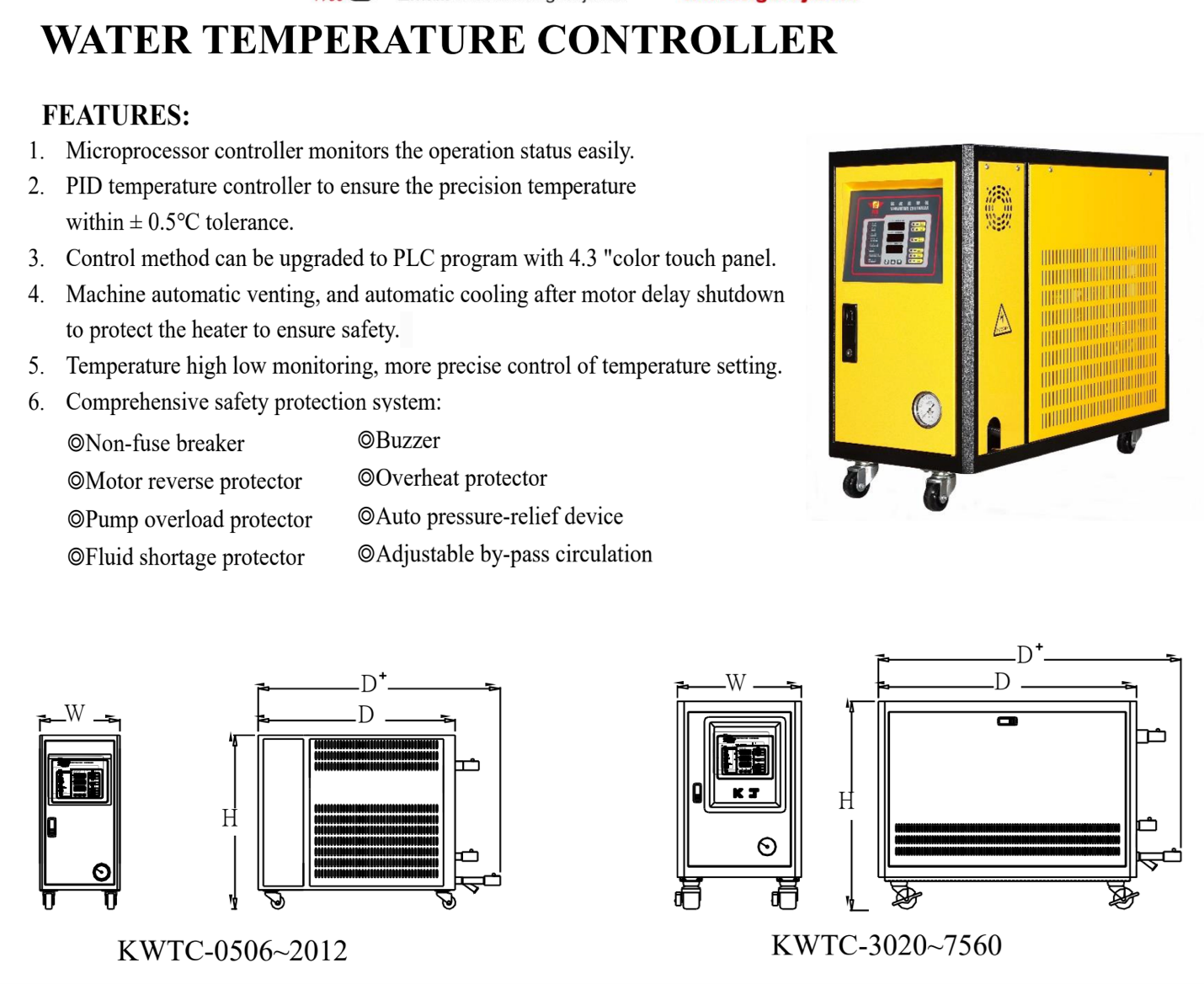

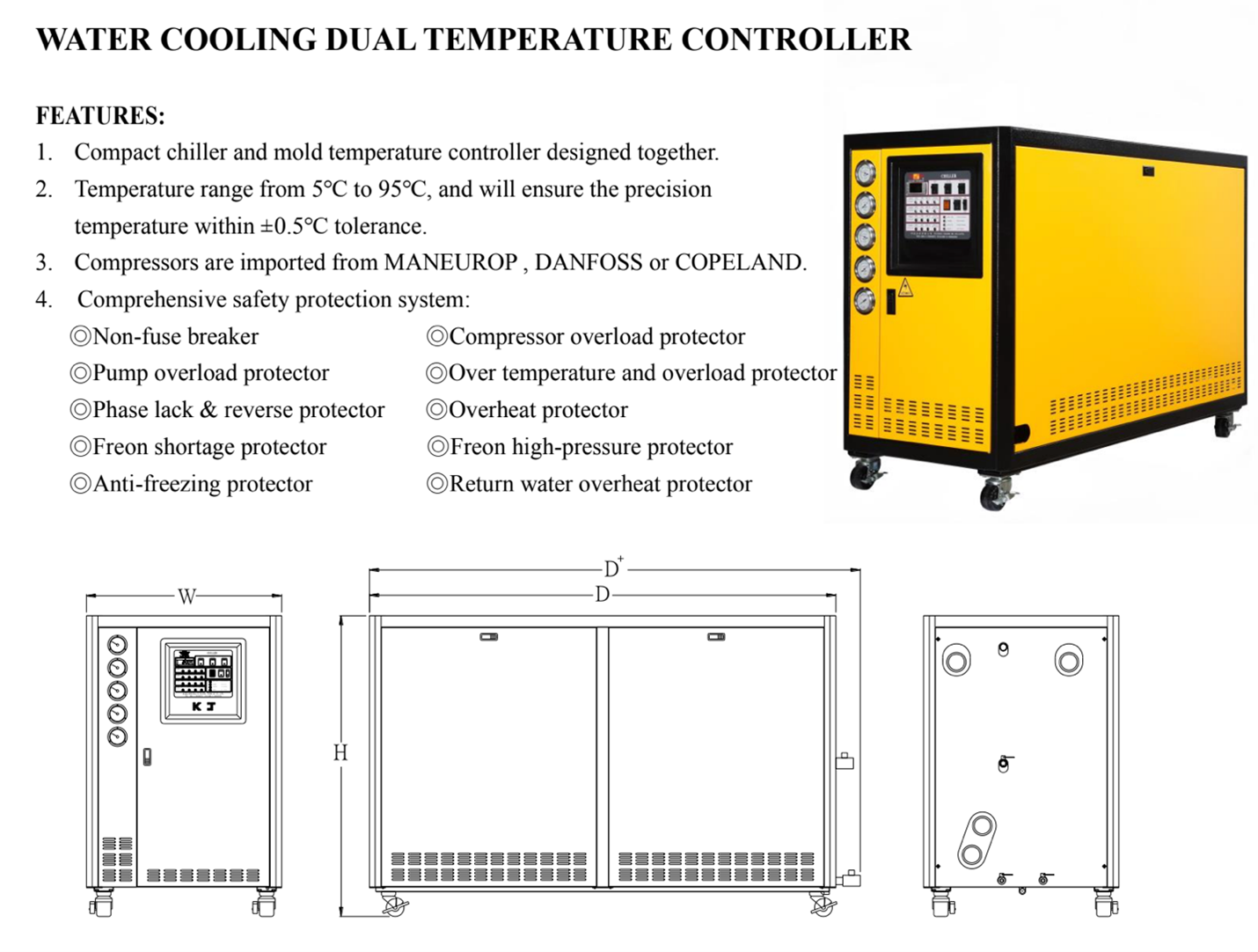

3. MOLD TEMPERATURE CONTROLLER

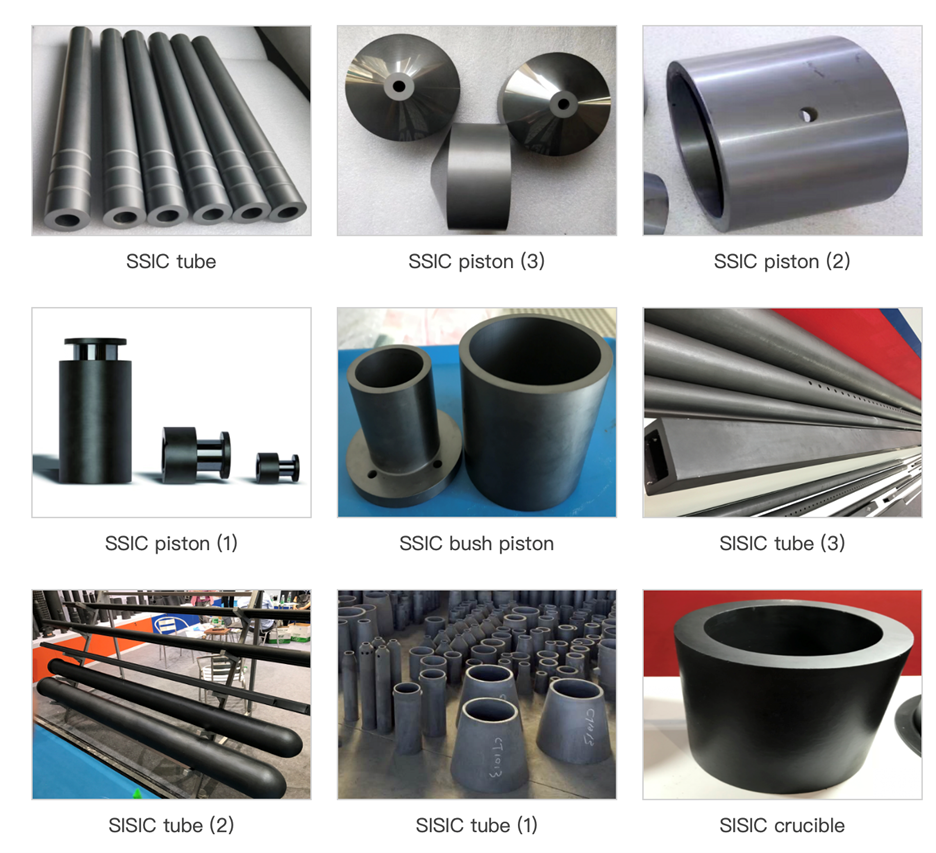

4. SiSiC Burner Tube & Nozzle

We main supplies Alumina ceramic, Zirconia Ceramic, Fused Alumina Ceramic, SIC/SSIC/ RBSIC, N-SiC Ceramic, Textile Ceramic, Mullite Ceramic, Cordierite Ceramic, Quartz, Piezo/PZT ceramic and other ceramic.

Our products cover lining bricks and tiles, ceramic pipes, tubes, roller and rods, ceramic ferrules, ceramic cuplocks, crucible, mortar and pestle, white/ black reaction plate, honeycomb, ceramic heating beads, spark Ignition plug, electronic insulation ceramic including LED Lamp, Piezo/PZT ceramic, grinding media balls and so on.

Competitive price SISIC silicon carbide ceramictube burner nozzle for kiln introduction SiSiC Burner Tube, this is reaction-bonded (silicon infiltrated) silicon carbide, being formed zero porosity by filling up open porosity with silicon metal (Si). Because of it’s zero…

Temperature of application: 1380 celsius Degrees

*Chemical Analysis in weight : SiC 85.07%

Size:300x112x68.6mm